Windsurf Mast Measurement

You've heard about the IMCS value and Bend Curve of windsurf masts. These are great ways to specify the characteristics of a mast. But if you really want to compare masts and improve the performance of your gear, you have to understand what these specs mean and how they're obtained. Or maybe you're just curious...

This article gives you all the in-depth information. We'll explain how masts are measured and the relevant calculations. We'll debug some common fallacies and show how you should interpret the data.

What defines a mast?

Sails are designed around a specific mast. To be able to replicate this 'mother mast', the sail designer should tell the mast manufacturer what the bend characteristics of this mast are. The bend characteristics are defined by four variables:

-

IMCS

-

Top%

-

Base%

-

Bend Curve Number

These 4 variables tell you if a mast will be compatible with your sail. There are also other variables that define the behaviour of a mast. For example the Reflex Value (how quickly a bent mast recoils to it's original position), or the Torsion Stiffness. But these variables are difficult to measure and hard to replicate. For now we'll just focus on the four mentioned above.

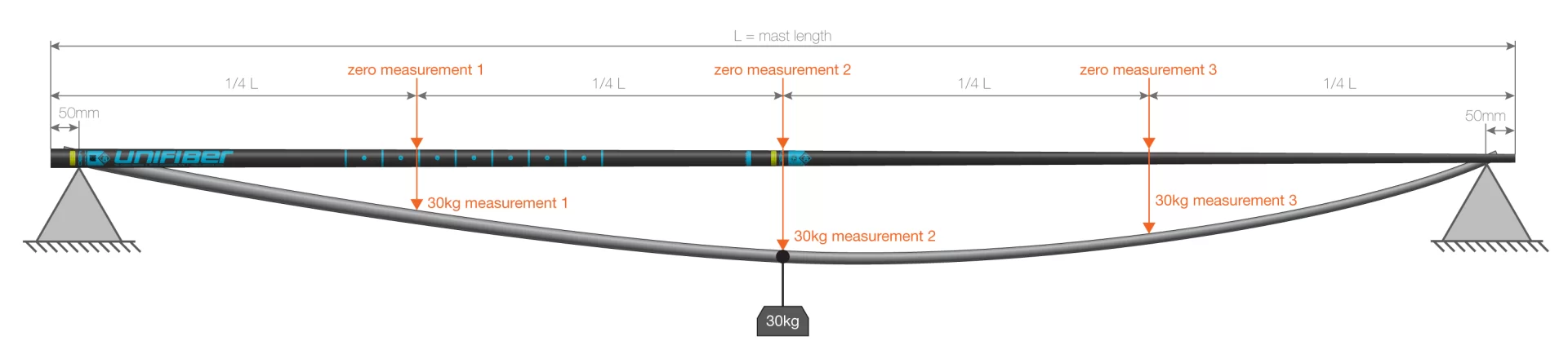

Method

Let's start with explaining the most common method for measuring a windsurf mast. This method is used throughout the industry. Every brand and factory uses this method, or a slight variation on it.

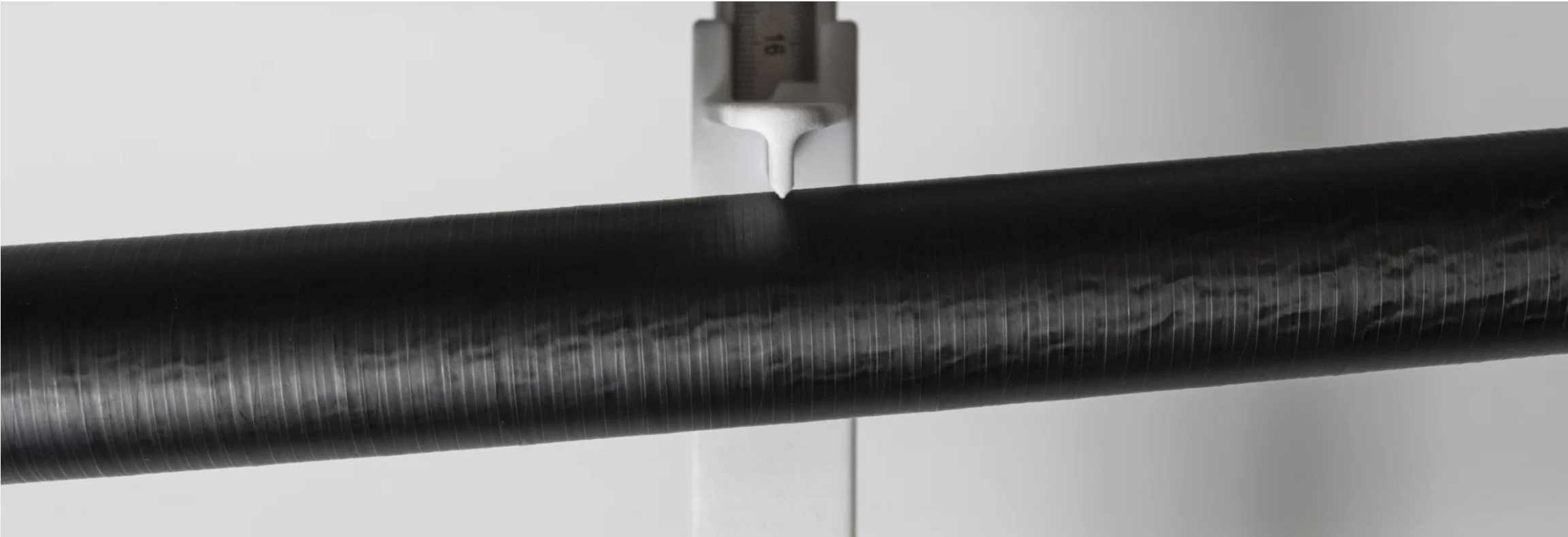

A schematic drawing of the set-up is shown in below image. The mast lays horizontally on 2 supports, each 5cm from the tips of the mast. A weight of 30kg is placed at the middle of the mast. The deflection of the mast is measured at 1/4, 1/2 and 3/4 of the mast's length. That's all the data you need.

Simple, right? But you have to keep a couple of things in mind:

- Without the 30kg weight applied, the mast will still bend a little under its own weight. That would mean that a 50% carbon (relatively heavy) mast will come out less stiff than a 100% carbon (relatively light) mast. To compensate this, we perform a 'zero' measurement: take the same measurements without the 30kg applied, and subtract those from the '30kg' results.

- Carbon composite is not a homogenous material. Due to the fibre orientation and the way the lay-up is made, each mast has some local differences in stiffness. This means that the bend characteristics of a mast can be slightly different when you rotate the mast. That's why we measure each mast 2 times: once with the labels facing upward and once with the labels to the side.

Calculation

We've obtained some raw data. How do we translate these into numbers that we can actually use?

IMCS is a measure for the average stiffness of the mast. The 'I' stands for 'indexed'. That means you can use the IMCS to compare the stiffness of 2 masts of different lengths. The IMCS formula translates the actual deflection of the mast to what the deflection would be if the mast were 460cm long.

IMCS stiffness = (length x length x length) / (460 x 460 x mid-deflection)

Top% is the relative deflection of the top (at 3/4 of the mast length).

Top% = (deflection at 3/4L) / (deflection at 1/2L) x 100%

Base% is the relative deflection of the top (at 3/4 of the mast length).

Base% = (deflection at 1/4L) / (deflection at 1/2L) x 100%

The Bend Curve Number shows the difference between top and base:

Bend Curve Number = Top% - Base%

Interpretation

Now we have the numbers. So what do they tell about the mast?

The IMCS is simple: it shows the average stiffness of the mast. Most brands stick to the more or less standardised stiffness for each mast length, but it is possible to find differences per mast. In our MAST KNOWLEDGE article we explain how this will influence your ride.

The Bend Curve Number is used as a definition for the bend curve category. The traditional classification is this:

| BC Number: | Category: |

| 0-6 | Hard Top |

| 7-9 | Hard Top - Constant Curve |

| 10-12 | Constant Curve |

| 13-15 | Constant Curve - Flex Top |

| 16-18 | Flex Top |

| 19-21 | Flex Top - Super Flex Top |

| >22 | Super Flex Top |

But this above categories are outdated. In the last 15 years no brands have used bend curve numbers less than 10 or greater than 17. Accordingly, the categories that Unifiber have used since 2011 are:

| BC Number: | Category: |

| <12 | Hard Top |

| 12-14 | Constant Curve |

| >14 | Flex Top |

The Bend Curve Number is a simplification that works 'good enough' for most windsurfers. But it doesn't tell the complete story. The Top% and Base% together show the actual bend curve. After all, a 64%-76% mast has a different curve than a 62%-74% mast, while both have a bend curve number of 12.

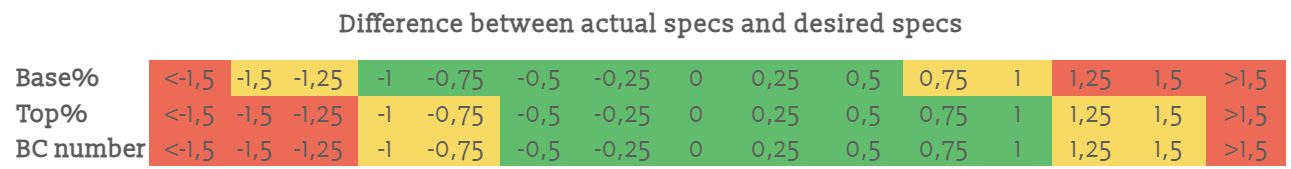

To see if a mast matches the desired specifications, Unifiber compare the Top%, the Base%, and the Bend Curve Number. See below table. If all three specs are in the green area, the mast makes a good match: even a pro windsurfer would have a hard time to notice the difference. If one of the specs is in the red area the mismatch will likely have a clear negative effect on the sail's performance.

If you would like to know more about bend curves, including the latest trends and developments, and how we developed our new mast curves, please see our BEND CURVE ARTICLE.

Precision, precision, precision

The method for mast measurement may be simple, but the difficulty lies in the required precision. If you measure with a tolerance of 1mm, the results could already be very misleading. Let's demonstrate with an example:

You have a 400 mast with specs: IMCS: 19,0 Base%: 64,1% Top%: 76,9% BC-number: 12,8

In theory, this mast should have the following deflection in the 30kg test:

Base: 100mm

Centre: 156mm

Top: 120mm

But you don't know the specs. So you measure the deflection with 1mm tolerance. It is very well possible that you measure the base deflection 1mm less than it actually is and at the same time you measure the top deflection 1mm more: Base:99mm Centre: 156mm Top: 121mm.

This measurement leads to the following results: IMCS: 19,0 Base%: 63,5% Top%: 77,6% BC-number: 14,1

You might conclude that this mast is 'out of spec', while in reality it would be a perfect fit...

This precision is influenced by more than just the accuracy of the measuring device. Friction between the mast and the supports can cause unreliable results, or the machine itself may bend a little under the 30kg load as well... It is the overall build-quality of the test set-up that makes the results more reliable or less so.

Do we speak the same language?

This method is very easy to replicate, but in the description are still some small details left for interpretation. For example: what material is used for the supports? Are the supports exactly the same height, or do we aim to keep the centreline of the mast exactly horizontal? There are multiple considerations.

These small differences between each test set-up also create small differences in the results they produce. This makes clear communication about the mast specs very difficult. For example, if one brand uses a 63%-76% curve, another brand might use the same curve and call it 63%-77%.

It is possible to 'translate' the results of one set-up to another, but that requires a lot of data to be compared. The most reliable way is to measure all the masts on one machine only.

Measurements versus the real world

We have to make one more important footnote. The curve of the mast in the test is not the same as the curve it makes in the sail. It is a very different manner of applying a load on the mast. In the sail the mast is loaded by compression: the bottom and top are pulled towards each other. It's not surprising that hanging 30kg in the middle has a different effect.

The method we described in this article is not the most realistic method available. So sail designers don't use this method to find the perfect luff curve for their sail. It is just a method of comparing one mast to another.