Technologie surfboard RRD

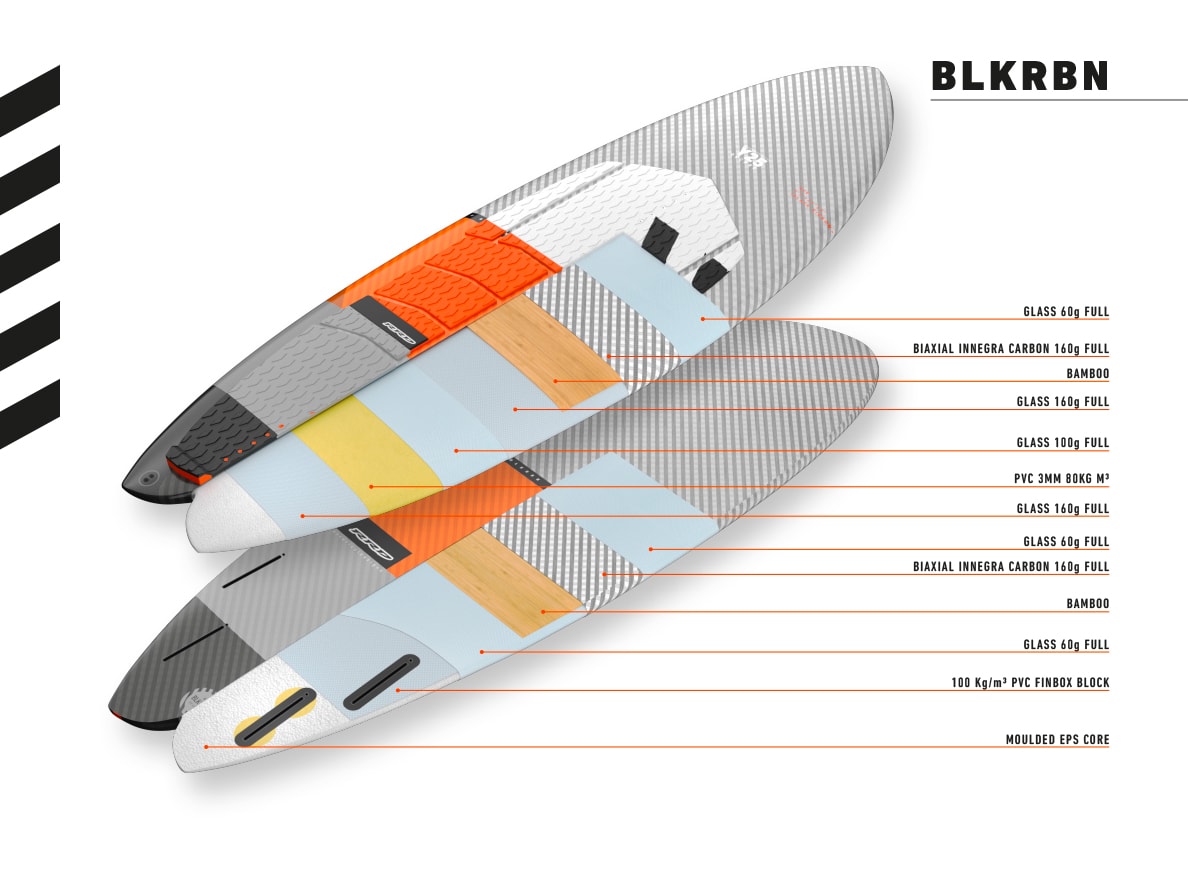

Taking lightweight kitesurfboards towards a ridiculously light & strong level! The Black Ribbon technology is the first line of kitesurfboards in the world made with Aerospace technology! The internal EPS core with only 15 Kg/m3 density is extra compact by the use of a special mold. This unique mold creates a perfectly sealed surface where the epoxy resin penetrates the layup at just the right amount, creating the perfect bond between each layer, but not too excessively that would simply add weight and no specific structural strength. For added reinforcements without significantly increasing weight, a 3 mm PVC foam layer is added on the deck to maximize impact resistance in addition to keeping the structure as light as possible while a full bamboo bottom sandwich layer creates the perfect blend between ding and dent strength on the bottom of the board. The entire structure is then fully covered with a complete layer of 160 grams Biaxial fibers combining a 45° mix between Carbon and Innegra fibers.

The new Black Ribbon construction provides a lightweight and strong kiteboard while maintaining a significant amount of flex compared to a full carbon layer.

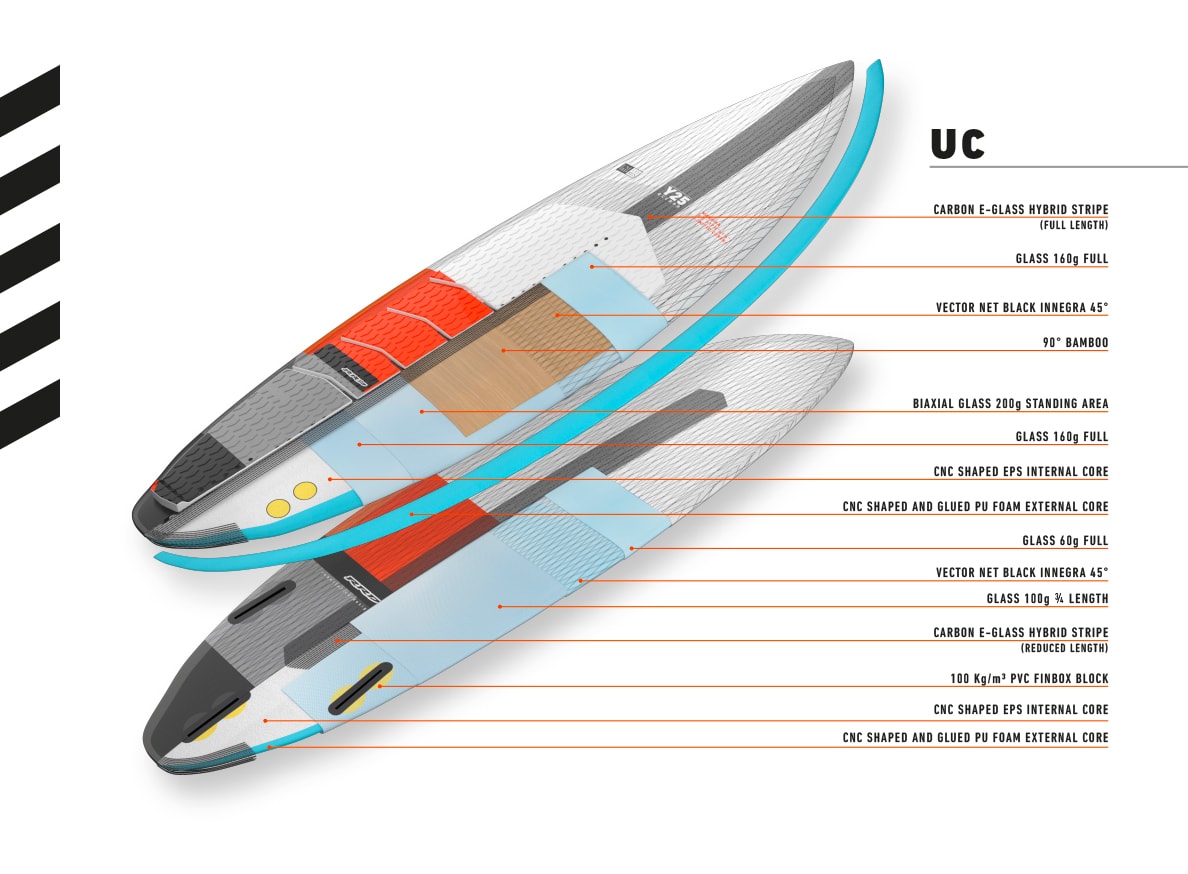

Maximizing lightweight does not only mean making a light board, but making a light board that LASTS. This is what we accomplished with the new UC construction.The EPS core is re-known for lighter weight/strength ratio and memory compared to PU foam but it has one big limit, it absorbs water in case of a hole or a crack through the laminate.

Fortunately, we have put together the best of the both worlds. In order to accomplish this feat, we have cut a 4 cms wide slice that runs throughout the entire outline of the board and have replaced the EPS external outline with 2 x PU outline slices that are glued to the EPS core. By adhering the PU to the EPS, we have created a 4 cms wide “waterproof” band that covers the entire rail, nose, and tail areas, keeping them totally waterproof in case of a crack through the laminate. The EPS core covers 80% of the board and creates a lively and buoyant center while the PU foam slices on the rails cover about 20% of the total foam volume. The PU rail slices combined with the deck and bottom carbon stringers laminated over the EPS core create a fantastic and unique pop and flex feel.

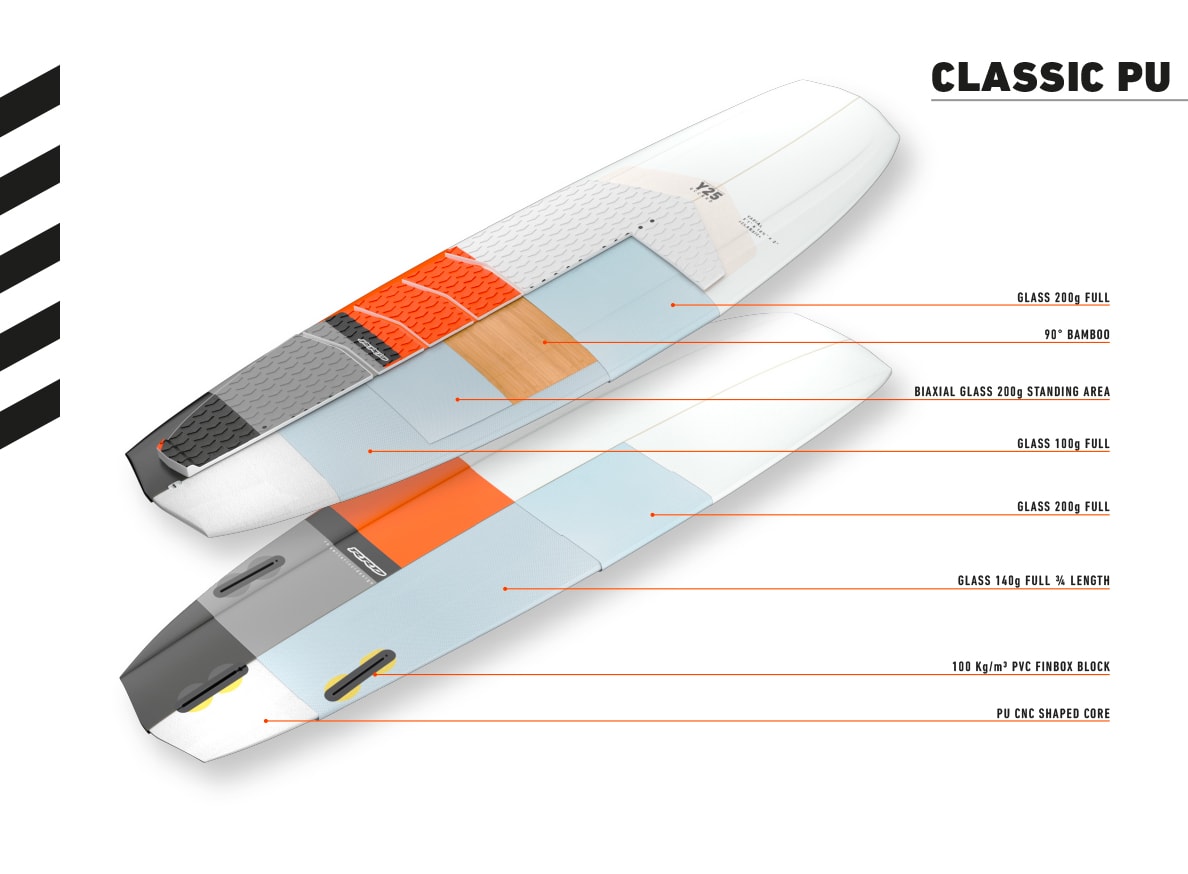

The Classic PU construction has been developed to create pure surfboards and to allow control over choppy waters. We have improved the weight and strength of the boards this year. We are now using a hi-volume lightweight pigment in the resin. This type of resin fills up the holes in the foam and reduces the amount of resin content in the glass fibers, making the boards lighter. The Classic boards have low fiber memory and low foam memory at the same time. This low memory gives the boards the right flex e feel. We recommend the Classic PU technology to the riders who love a comfortable pure surfing feel under their feet.

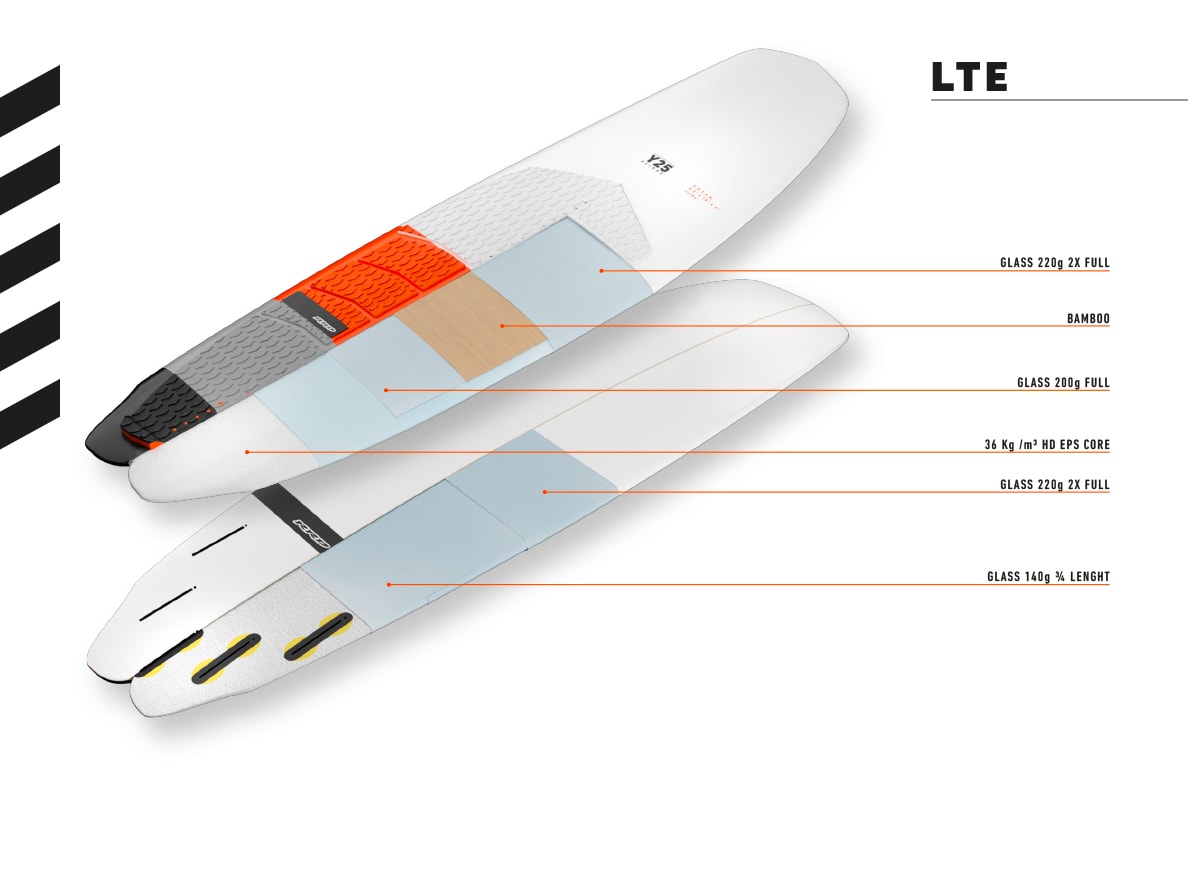

The new LTE technology comes straight from the ultimate molded surfboards technology which consists of a high definition EPS core, made with a high definition “Super EPS“ mold, which is then injected with 36 Kgs/m3 density bit’s. This phenomenal core is so strong that you could ride it on the water without any lamination on it! The Full Glass layup makes the board super flexible to ride and really strong to impact resistance, creating unmatched durability.