Technologie kite RRD

We are passionate about combining quality, technology, strength, and artisanal design that is functional and accessible to everyone in watersports. We make products that we love, that last, and that can be used by everyone, not only the elite watersports enthusiasts.

We pride ourselves in using the latest technologies combined with creative design, added reinforcements, and genuine Italian style: this is what RRD stands for. We do not cut corners when it comes to our equipment. In fact, where our competitor’s equipment is weak, RRD equipment is strong.

The watchwords for RRD are style, quality, and strength following the pure Made in Italy vision, supported by the continuous commitment to research and development. Using the best available materials and production processes, combined with the meticulous attention to detail, we create aunique piece of equipment with character, harmony, and performance.

| leading edge reinforcements | pu bridle reinforcements | kevlar bridle pads | ||

|

|

|

||

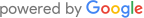

| Every panel of any inflatable structure, from the struts to the leading edge, is built with a special heavy duty stitching system. The stitching areas are internally reinforced with a strip of adhesive dacron (Insignia), creating a solid base for durability. Kevlar is then wrapped around every exposed LE Seam to provide further protection. | Bridle attachment points are reinforced with a soft PU external protection an and internal double adhesive dacron patch, to increase durability. | Kevlar reinforcement scuff pads located on the wear points of the leading edge protecting the Dacron from constant abrasion where the bridles make contact with the leading edge. |

| quick airflow valve | one pump clips | cnc laser cut graphic panels | ||

|

|

|

||

| A singular point, one way, air flow valve, inflation and deflation system with a special moulded protection cap.This new valve has a smaller diameter and pliable base that allows the perfect leading edge shape and adds to the lifespan of the kite. | One pump hose clamps that prevent unwanted airflow between struts and leading edge. Each clamp is covered with neoprene to prevent wear and damage to the kite. | Our bold graphics are designed with CNC laser cut panels made with canopy fabric firstly glued and then triplestitched together. This way we can avoid massive screen printining on the kite, reducing it’s deteriorating effect and making each graphic panel effectively a reinforcement on the kite body it’self. An RRD exclusive design feature now copied by some other kite brands. |

| multi-point line settings | bridle anti-tangle device | 45º crrosed fabrics le/strut reinforcements | ||

|

|

|

||

| Multiple points of connection provide a multitude of adjustments to the flying characteristics of the kite such as depower, bar pressure, turning speed, and turning radius. These changes affect jumping, kite loops, slack, drift, and water relaunch. | A small batten that connects from the trailing edge to the leading edge that prevents the bridles from wrapping around the wingtip during launching or water relaunching. It also allows for storage of the bridles when packing the equipment after a session. | In correspondence of each strut and it’s connection point onto the leading edge, we have created a specific 45° crossed fibers double ripstop reinforcement that spreads the load of the strut onto the body of the kite during hard crashes, drastically reducing the potential canopy breakage of the kite. |

.png)